Description

Carbon dioxide spherical tank

Carbon dioxide spherical tank is a spherical tank with uniform stress on the shell. Under the same diameter and working conditions, the membrane stress of the spherical container is only half of the circumferential stress of the cylindrical container with the same thickness. The corresponding pressure bearing capacity is strong, and the surface area of the spherical shell under the same volume is the smallest and the weight is light.

Introduce

Characteristics of carbon dioxide spherical tank

Carbon dioxide spherical tank is a spherical tank with uniform stress on the shell. Under the same diameter and working conditions, the membrane stress of the spherical container is only half of the circumferential stress of the cylindrical container with the same thickness. The corresponding pressure bearing capacity is strong, and the surface area of the spherical shell under the same volume is the smallest and the weight is light. However, due to the large volume of spherical storage tank, the spherical shell plate needs to be formed by the manufacturer and assembled and welded by the installation unit on site. It is difficult to manufacture and install, and the technical requirements are relatively high.

Thermal and cold insulation facilities of spherical tank

Under the influence of earthquake, wind pressure, rain and fire water pressure, the cold insulation structure can ensure the effect of thermal insulation without damage.

In principle, the thickness of cold insulation material is the thickness required to ensure that there is no dew on the surface of outer material.

The shell of liquid carbon dioxide spherical tank is generally made of polyurethane foam because it has good cold insulation performance and is covered on the spherical shell with glass fiber cloth and adhesive.

Double shell spherical tank Generally, the expanded perlite is filled between the inner and outer interlayer, or the polyurethane is filled and solidified, or the cold insulation is carried out by pumping air.

Requirements for foundation of spherical tank

In the case of 1mm uneven subsidence, one pillar will produce about 10% higher stress than other pillars. If the safety factor is 1.7 when designing the column Under the condition of uneven sinking of 7mm, the bearing capacity of the strut will be exhausted, resulting in axial bending. In order to sink as evenly as possible. The foundation shall be designed as a torsionproof ring foundation. In addition, it is also necessary to adopt annular foundation for spherical tanks set in seismic area.

Based on the fact that the spherical tank needs overall heat treatment after welding, the spherical tank foundation should adopt the reserved hole structure, and the anchor bolts should not be embedded. Because during the heating and cooling process of the spherical tank, the strut will move with the thermal expansion and cold contraction of the shell. The head of the anchor bolt exposed to the foundation surface will hinder the displacement of the pillar. Moreover, the reserved hole structure is also conducive to the necessary adjustment of the pillar position in the installation process to ensure the installation quality of the spherical tank.

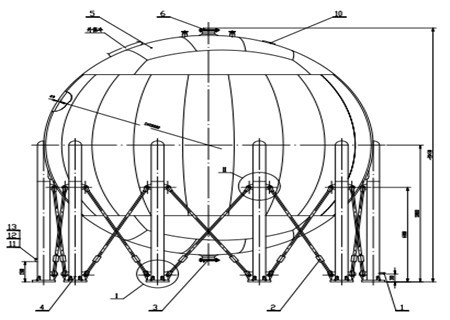

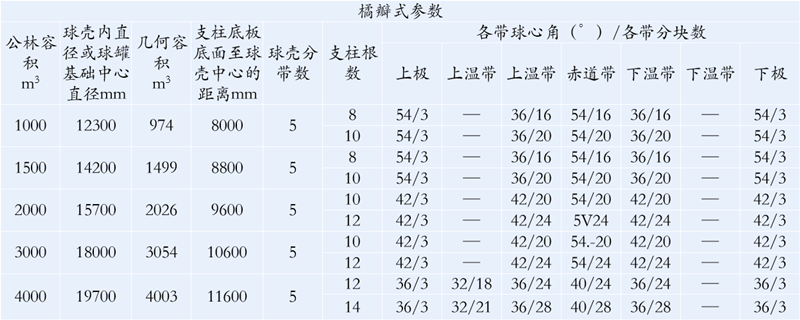

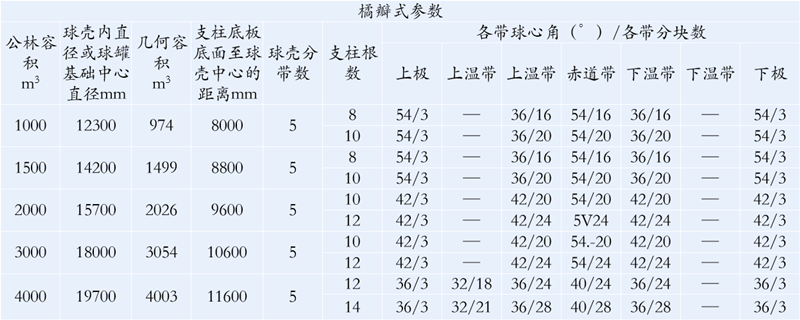

Spherical tank type and geometric dimension

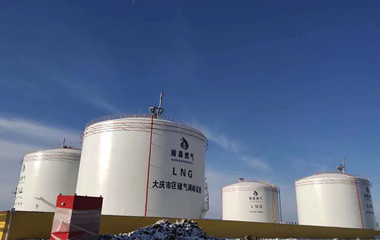

Case

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]