Hotline

+86 512-81666096圖135、About 2000m ³ LNG storage tank weld inspection - Doer equipment

Classification:Forum PublishTime:2019-12-23 13:46:42

About 2000m ³ Weld inspection of LNG storage tank

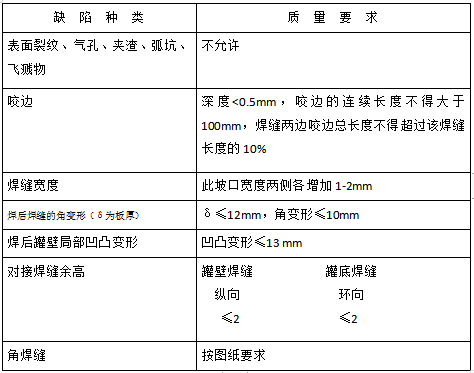

About 2000m ³ For the weld inspection of LNG storage tank, the weld must be visually inspected, and the weld height, width and undercut amount shall meet the requirements in the table below.

List of weld appearance quality requirements

Weld detection shall be carried out according to the requirements of design documents and specifications. The specific requirements are as follows:

1. The butt weld of the main body of the inner groove shall be subject to 100% RT nondestructive testing according to JB / t4730.2-2005, and it is qualified at level II.

2. The butt weld of the main body of the outer groove shall be tested by 100% Pt coloring according to JB / t4730.2-2005, and it is qualified at Level I.

3. The fillet weld between the inner and outer groove bottom plate and the cylinder shall be subject to 100% Pt coloring inspection, and the leakage inspection shall be carried out with a vacuum box.

4. Pipeline inspection requirements: for liquid phase pipeline, all butt welds shall be subject to 100% RT radiographic inspection, and class II is qualified; For gas phase pipeline, when DN > 20, 100% radiographic inspection shall be conducted for butt weld, which is qualified in grade II; When DN ≤ 20, Pt is used for detection, and class I is qualified; PT test was conducted for all fillet welds, and it was qualified as grade I. All tests shall be carried out in accordance with JB / t4730.2-2005.

Prev: 圖134、About 2000m ³ Selection of welding method for LNG storage tank - Doer equipment

Next: 162,What are the storage methods of LNG cryogenic storage tanks( 1) -Doer equipment

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]