Hotline

+86 512-81666096圖134、About 2000m ³ Selection of welding method for LNG storage tank - Doer equipment

Classification:Forum PublishTime:2019-12-21 13:50:02

About 2000m ³ Selection of welding methods for LNG storage tanks

2000m ³ Selection of welding method for LNG storage tank:

All welds of the outer tank body are welded by manual arc welding, and the butt welding of the inner tank body is constructed by argon arc double gun symmetrical welding. This method has strong adaptability compared with automatic welding and is suitable for the welding of any part of the tank body; Compared with arc welding, it is easy to ensure welding quality, fast welding speed and high work efficiency.

Welding sequence of tank bottom plate:

Spot welding shall be carried out after the bottom plate of 1 inner tank is laid, and the welding shall be carried out after the wall plate assembly and foundation reach the design strength.

During the welding of 2 plates, the short weld shall be welded first, and then the long weld shall be welded. The segmented backward skip welding method shall be adopted for the initial weld bead. During the welding of long weld, the welders shall be evenly and symmetrically distributed, and the segmented backward skip welding shall be conducted from the center to the outside.

3 for the welding of annular plate, the butt joint shall be welded first, then the fillet weld between tank wall and bottom plate, and finally the weld between annular plate and middle plate.

4 the fillet weld connecting the tank bottom and the tank wall shall be welded after the longitudinal weld of the bottom ring wall plate is completed, and several welders shall carry out sectional back welding in the same direction from the inside and outside of the tank.

5. The welding of contraction joints shall be performed by welders uniformly and in sections, and shall be completed continuously.

Welding sequence of tank wall plate:

1 the longitudinal seam shall be welded first for the welding of wall plate. After the longitudinal seam of two adjacent strip plates is welded, the circumferential weld between them shall be welded. The longitudinal weld shall be welded from bottom to top.

2 during welding, the outer side shall be welded first and then the inner side. During circumferential seam welding, welders shall be symmetrically and evenly distributed, and back welding shall be carried out in sections along the same direction, with a spacing of 350 ~ 450mm.

Welding sequence of tank roof:

1. For the welding of the top plate, the inner weld shall be welded first, and then the outer weld. The radial long weld shall be welded symmetrically at intervals, and the back welding shall be carried out in sections from the center to the outside.

2. Weld Internal intermittent welds first, and then external continuous welds; The circumferential short weld shall be welded first, and then the radial long weld shall be welded. The long weld shall be welded backwards in sections from the center to the outside.

3. The welding of top plate and edge wrapped angle steel shall be symmetrically distributed, and the back welding shall be carried out in sections along the same direction.

Measures to prevent welding deformation:

1. Anti deformation measures for bottom plate

After bottom plate assembly, anti deformation fixtures shall be installed at both ends of each plate before welding, and back bars shall be pressed on both sides of long plate before welding.

2. Anti deformation measures for internal and external fillet welds:

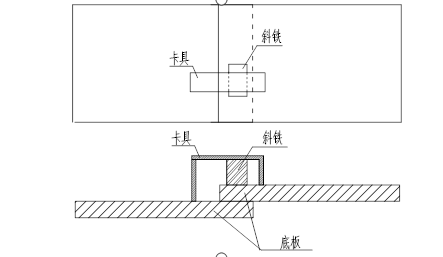

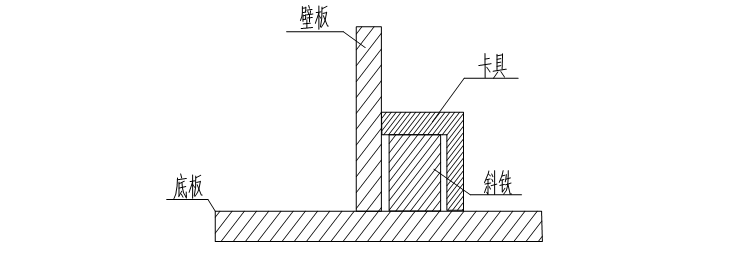

After the first and second wall plates are welded (see attached figure-1 for the sequence of strip plates), carry out assembly and spot welding of fillet welds, spot weld the outside first, then the inside, and weld 100mm every 300mm. Install anti deformation fixtures before welding, as shown in the following figure:

Prev: 圖133、About 2000m ³ Technical requirements for welding of LNG storage tank - Doer equipment

Next: 162,What are the storage methods of LNG cryogenic storage tanks( 1) -Doer equipment

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]