Description

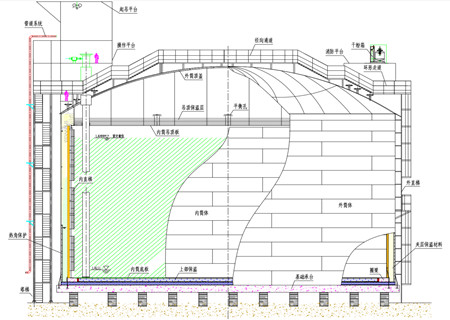

It adopts the flat bottom cylinder bimetal full containment tank structure, double metal wall, flat bottom, inner suspended roof, outer vault, vertical cylinder and full containment structure, which is composed of main vessel, secondary vessel, bottom insulation, sandwich insulation, ceiling insulation, steel structure at the top of tank, tower ladder, equipment valve, electrical instrument and foundation platform.

Introduce

Brief description:

The liquid ammonia is stored in the inner tank (main container) of the full tank, and the outer tank (secondary container) is used to hold the evaporated gas and cold insulation materials. When the inner tank leaks, the outer tank can store part of liquid ammonia effectively. The inner and outer tanks are flat bottomed and cylindrical metal tanks. The top of the inner tank is suspended in the support structure of the outer tank vault by suspenders. The outer tank vault is spherical and the top support structure is ribbed ring grid. The foundation of liquid ammonia storage tank adopts concrete elevated platform structure.

The double metal full tank ceiling structure has the following advantages:

① The structure of full tank ensures that in case of inner tank leakage, part of liquid ammonia liquid can be effectively stored in outer tank, and the evaporated gas can be recovered or sent to flare through recovery pipeline.

② According to the specification, the fire prevention distance of full tank structure is the least and the land utilization rate is high.

③ The inner tank design does not need to consider the internal positive pressure and interlayer vacuum load, so the inner tank will not be affected in case of overpressure or vacuum accident, and the safety is higher.

④ It is not necessary to consider the pipe compensation in the interlayer when connecting the ceiling structure. For the inner tank with dome roof structure, both ends of the pipe are respectively fixed with the inner tank and the outer tank, while for the ceiling tank, only one end of the pipe is fixed on the top of the outer tank, and the other end can be freely retracted.

Technical parameters of large liquid ammonia low temperature full capacity tank:

Material selection of main equipment:

1. Material selection of main container and secondary container of equipment

According to the basic design requirements of bimetallic full tank operation conditions, 16MnDR steel plate is selected for the main vessel and secondary vessel.

2. Material selection of equipment low temperature pipe fittings

The low temperature liquid phase and gas phase pipelines of the equipment (from the suspended roof to the junction point, including the inlet and outlet pipes of nitrogen purging in the interlayer space, etc.) are made of low temperature seamless steel pipe, and the material is Q345E.

3. Material selection of normal temperature pipe fittings of equipment

The normal temperature pipes and fittings are made of carbon steel with the grade of 20, and the executive standard is GB / t8163-2018 seamless steel pipes for fluid transmission. The fittings are made of 20, and the executive standard is GB / t12459-2017 steel butt welded seamless pipe fittings.

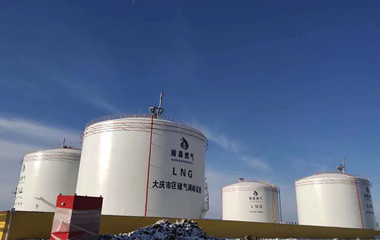

Case

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]