Description

LNG Gasification Station Storage Tank

Vacuum LNG cryogenic liquid storage tank is a kind of commonly used and advanced cryogenic liquid long-term storage equipment, which has the advantages of large storage capacity, adjustable pressure, low evaporation rate, safety and reliability. It is widely used in LNG filling station, LNG gasification station, LNG emergency peak shaving station and other projects. The storage tank adopts double-layer cylindrical structure, with interlayer filled with insulation material pearlite and vacuumized. It is mainly composed of inner tank and outer tank, insulation structure, pipeline system and safety accessories.

Introduce

Storage and transportation container

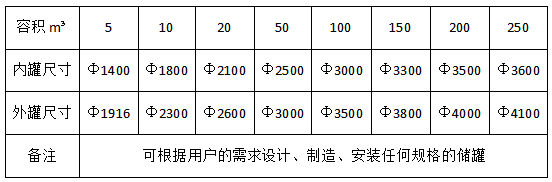

The size and specification of storage tanks produced by our company are different, 5m3-250m3, 0.7mpa-2.16mpa, vertical, horizontal and non-standard. Special low temperature pressure vessel with double-layer high vacuum insulation structure, similar to household thermos structure and insulation principle, is mainly used for storage and transportation of liquid industrial gases (LO2, LN2, LAR, lco2) at - 196 ℃;

The cryogenic vessels designed and produced by our company are in accordance with the provisions of GB 150-1998 steel pressure vessels and gb-18442 fixed vacuum powder insulated cryogenic liquid storage tank, and are supervised by the regulations for safety technical inspection of pressure vessels issued by the State Bureau of quality and technology inspection

Low temperature test has been done for each storage tank before leaving factory to ensure 100% qualified rate of equipment and reliable heat preservation. Special perlite for storage tank is used for low consumption storage. The parameters meet the requirements and vacuum degree is ≤ 2.0pa. In order to ensure that the interlayer of low temperature storage tank has a long service life, the inner tank and interlayer are subject to strict air pressure, air tightness test and helium mass spectrometer leak detection, and the leak rate is ≤ 1.0pa × 10-6pa L / s compression seal, vacuum should not leak, a variety of safety accessories use more assured.

Double safety valve double rupture disc configuration, the number of safety valves than other manufacturers, basically every closed pipeline has a safety valve.

The three-way valve design is adopted before the safety device, so there is no need to worry about the safety device being closed, which is more convenient for the maintenance and replacement of safety accessories. Small problems are fully considered to the needs of users.

The tank liner is made of high-quality stainless steel plate and passivated. It is equipped with automatic pressurization tank valve, which can automatically pressurize.

The storage tank can be equipped with gas saving device.

When the pressure of the cryogenic liquid storage tank exceeds the set pressure, the tank automatically uses gas to depressurize; When the pressure of cryogenic liquid storage tank is lower than the set pressure, the tank will automatically open the pressurization device to pressurize. So that the whole cryogenic liquid storage tank pressure is in a constant state.

Specification sheet

Case

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]