Hotline

+86 512-81666096127、Introduction of LPG water bath gasifier - Doer equipment

Classification:Forum PublishTime:2019-12-03 16:02:21

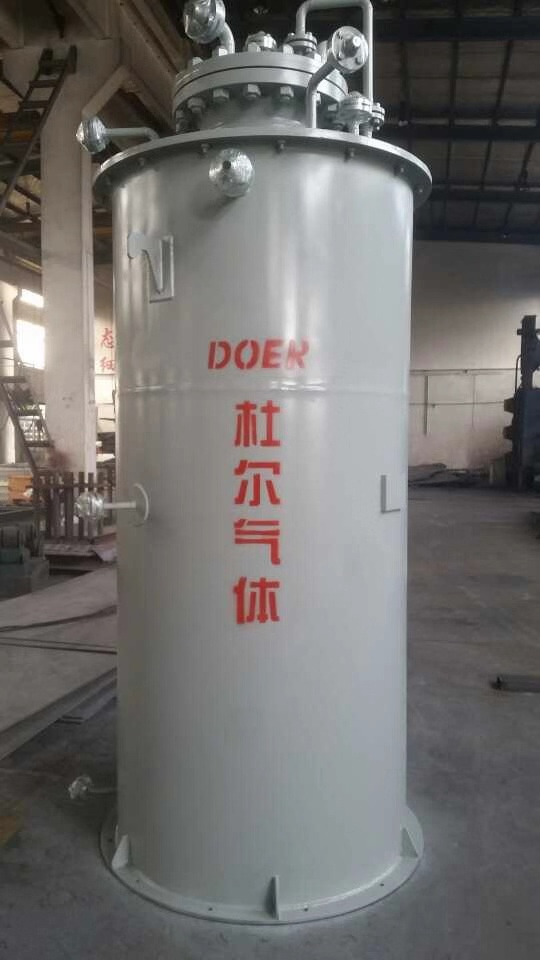

Introduction of LPG water bath gasifier

1、 Features:

LPG water bath gasifier has the advantages of simple operation, convenient maintenance and affordable price. The gasification capacity ranges from 5kg to 300kg per hour.

The process structure of LPG water bath gasifier is firm and durable, and has anti-corrosion performance.

The float valve device can prevent liquid from seeping through the pipeline.

The safety relief valve can automatically discharge the overpressure gas and then close it automatically.

The two-stage electronic temperature controller automatically adjusts the water temperature of 60 to 70 degrees, and the air supply is stable.

Low water level protection control circuit to ensure that the heating element is burned due to water shortage.

2、 Technical characteristics:

Design pressure of LPG water bath gasifier: 2.7mpa (27kg / cm2);

Hydraulic test pressure: 3.3Mpa (33kg / cm2);

Air tightness test pressure: 2.7mpa (27kg / cm2);

Opening pressure of safety valve: 1.76Mpa (17.6kg / cm2);

Operating temperature: 50 ℃ - 80 ℃.

3、 Instructions for use:

Pipeline: carefully see the words marked on the LPG water bath gasifier, and whether the liquid phase inlet and gas phase outlet are connected to the corresponding pipeline.

Water injection: add pure distilled water or pure water without impurities at the water injection point marked on the gasifier until the overflow pipe at the bottom of the furnace overflows.

Power supply: open the explosion-proof chamber cover on the furnace body, connect the power supply directly to a, B, C and N on the wire board inside the electric control box, where n is the zero line, and then connect it from the U, V and W ends of the electric control box to the three independent contacts on the heater in the explosion-proof junction box of the chemical gas furnace (there are six contacts on the heater, three of which are connected together). Also connect the 2 and 3 contacts marked on the wire board of the electric control box to the 2 and 3 ends marked on the wire board in the explosion-proof junction box of the chemical gas furnace.

Cover and tighten the open explosion-proof compartment cover.

The temperature controller, relay and heating pipe in the bin cover have been adjusted and measured before leaving the factory. Non professionals are not allowed to adjust the LPG electric hot water bath gasifier at will.

Prev: 126,LNG gasification station - Doer equipment

Next: 162,What are the storage methods of LNG cryogenic storage tanks( 1) -Doer equipment

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]