Hotline

+86 512-81666096113,Air pressure, air tightness test and vacuum test of outer tank before tank construction (Part 2) - Doer equipment

Classification:Forum PublishTime:2019-11-13 13:05:17

Air pressure, air tightness test and vacuum test of outer tank before tank construction (Part II)

6) External tank vacuum test of storage tank

◇ slowly drain the water outward through the centrifugal pump placed outside the tank to make the inner cylinder reach the suction valve, set the suction pressure to -0.3kpa, open the root valves of the suction valve one by one, and detect whether the suction valve sucks. If not, re detect the suction valve.

◇ close the root valve of the vacuum suction valve, drain water outward slowly until the tank pressure reaches -0.5kpa, maintain the vacuum degree for half an hour, and the capping is qualified if there is no abnormal deformation.

7) Cleaning of inner tank

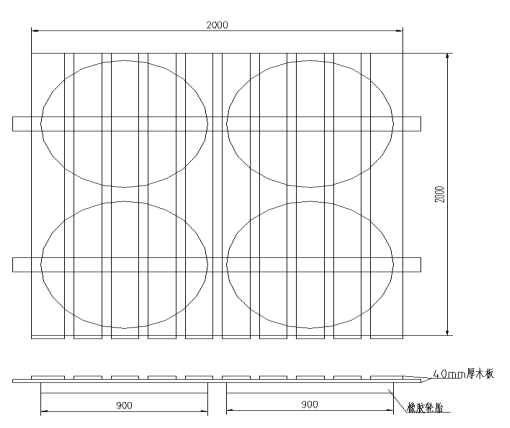

After all the tests of the inner pipe are completed, place a leather raft made of rubber tires in the inner tank, sit on the raft and clean the tank wall with a high-pressure water gun from top to bottom. The configuration of cleaning solution is practical. Add water with detergent. Four tires with a diameter of 900mm are used to make the raft, which are arranged in four squares, tied with ropes, and placed with 40mm thick wooden board

On the raft. As shown below:

8) Inner tank bottom vacuum box test

The second vacuum tank test shall be conducted for the welds on the inner tank bottom plate after the inner tank water is drained. The test method and pressure shall be the same as that of the first vacuum tank test.

9) Safety precautions

A. Strict technical disclosure shall be carried out before the hydrostatic test to ensure that the personnel participating in the test carry out the operation test one by one according to the correct steps, so as to avoid serious consequences caused by misoperation.

B. The test area (within 15m around the tank) shall be delimited during the hydrostatic and air tightness test, and only operators can enter the test area.

C. The air tightness test is dangerous and needs to be carried out by experienced people during the day. The compressor shall be supervised by a specially assigned person during the test. No one is allowed to enter the safe area during pressurization.

D. The vacuum pumping test shall be conducted during the temperature rise period of the day to avoid overpressure caused by pressure drop caused by temperature drop.

E. It is forbidden to carry out any construction work on the tank during the test phase.

F. The power supply of submersible pump must ensure safe insulation when working in the tank.

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]