Description

Liquid Argon Air Heated Gasifier

This series of vaporizers use the heat of air to heat the low-temperature liquid in the heat exchange tube. The fins of the heat exchange tube absorb the heat in the air and conduct it to the low-temperature liquid in the tube, so as to gasify it into gas. Air temperature gasifier does not need electricity or steam. It is a new type of high-efficiency and energy-saving gasification equipment. It has no operating parts, maintenance and noise. It is widely used in the gasification of low-temperature liquids such as liquid oxygen, liquid nitrogen and liquid LNG.

Introduce

Product structure and working principle

This series of gasifiers are tubular and connected by star shaped finned tubes. The unique "bridge" connection improves the gasification capacity and flexibility of the equipment. The connection between the fins does not need welding, with small internal stress, compact structure, uniform arrangement, beautiful and durable.

LNG air heated gasifier uses natural convection of air to heat the low temperature liquid in the heat exchange tube and make it evaporate into gas completely; It is a kind of high efficiency and energy-saving heat exchange equipment with air temperature and heating vaporization function, which can replace heating vaporization products. Vaporizer is the low temperature liquid gas through heat exchange, vaporization into a certain temperature of gas, according to the purpose is divided into high, medium and low pressure three kinds.

The high-pressure vaporizer vaporizes the liquid oxygen, liquid nitrogen, liquid argon and liquefied natural gas pressurized by cryogenic liquid pump into high-pressure gas and fills the steel cylinder. The low-pressure vaporizer vaporizes the low-temperature liquid in the storage tank into low-pressure gas, which is transported to the use site through the pipeline through the pressure regulating device. Air heated vaporizer is a high efficiency and energy-saving product. Compared with water bath electric heating vaporizer and steam heating water bath vaporizer, it can save a lot of electricity or steam.

The structural features of the carburetor can ensure the normal operation of all parts under cryogenic temperature, avoid seal freezing, good sealing, safe and reliable, non corrosive, and long service life. Using special ¢ 120, ¢ 160, ¢ 200 large diameter special aluminum finned tube, defrosting speed is very fast.

The welding seams of all parts of the carburetor are welded by argon arc welding. The welding seams are neat, beautiful and free of air hole defects. Optimize the process design to minimize the pressure and ensure the flow rate within the safe range.

Main technical parameters

Suitable media: LNG, ng, CNG, LO2, LN2, LAR, lco2, NH3, LPG, etc;

Working pressure: 0.1-40mpa;

Gasification capacity per unit: 20-10000nm ³/ h. No matter how large the size is, please choose multiple combination type;

Equipment classification: vaporizer, heater, supercharger, etc.

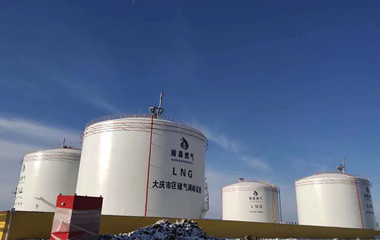

Small LNG gasification skid mounted station is a complete set of equipment which integrates LNG storage tank, air temperature vaporizer, pressure regulator, metering device and safety control device, and can directly provide gas source to residential quarters and industrial users.

Star finned tube

Star shaped finned tube is the core component of vaporizer, which is the result of heat absorption and gasification. The material of finned tube is antirust aluminum. The commonly used fins of finned tube are 8 fins and 12 fins. The outer diameter of finned tube mainly consists of two specifications, φ 160mm and φ 200 mm, usually used for large-scale vaporization φ 200mm。

Material and technology

All parts are made of aluminum alloy and stainless steel with excellent oxidation resistance and high performance. Before leaving the factory, the product is dried with nitrogen according to the oxygen standard to ensure the product quality and use more safely.

Structural advantages

1. No energy consumption, no pollution, green environmental protection; It is easy to install and maintain;

2. Special aluminum heat exchanger, high efficiency, lightweight design, long service life;

3. Special super large diameter special aluminum heat exchange tube, defrosting speed is very fast, effective inner fin structure, greatly improve the heat transfer effect of heat exchange tube;

4. The "bridge" type connection is beautiful and generous, which can eliminate the stress caused by heat expansion and cold contraction of each part during working;

5. Special anti-oxidation treatment process of heat exchange tube surface was carried out

6. Optimize the process design to minimize the pressure drop and ensure that the flow rate is controlled within a safe range;

7. Adequate design bath volume;

8. Advanced high pressure tube composite technology makes the pressure tube fully contact with the heat exchange tube to ensure the heat exchange efficiency;

9. All gasifiers are completely cleaned and manufactured according to the oxygen service standard, so it is safer to use; It can be designed and manufactured according to electronic standard.

Prev: Ambient Air Vaporizer

Next: LNG Air Heated Vaporizer

Case

News

- 216、Advantages of Double Metal Full Capacity Tank … [2023-05-09]

- 215、Design principles for low-temperature storage … [2023-05-09]

- 214、Low temperature storage tank safety education … [2023-05-09]

- 213、Objectives of project construction management-… [2023-05-09]

- 212、Quality service advantages of Doer large low-t… [2023-05-09]

- 211、Advantages of Doer Large Low Temperature Stora… [2023-05-09]

- 216、Design scope of atmospheric and low-temperatur… [2023-05-08]

- 215、Process flow of low-temperature LNG storage ta… [2023-05-08]

- 214、Testing methods for low-temperature argon stor… [2023-05-08]

- 213、Performance Description of Low Temperature Eth… [2023-05-08]